From the MCRFB news archives: 1963

From the MCRFB news archives: 1963

Cadence LP Smashes Most Marks in History of Disks

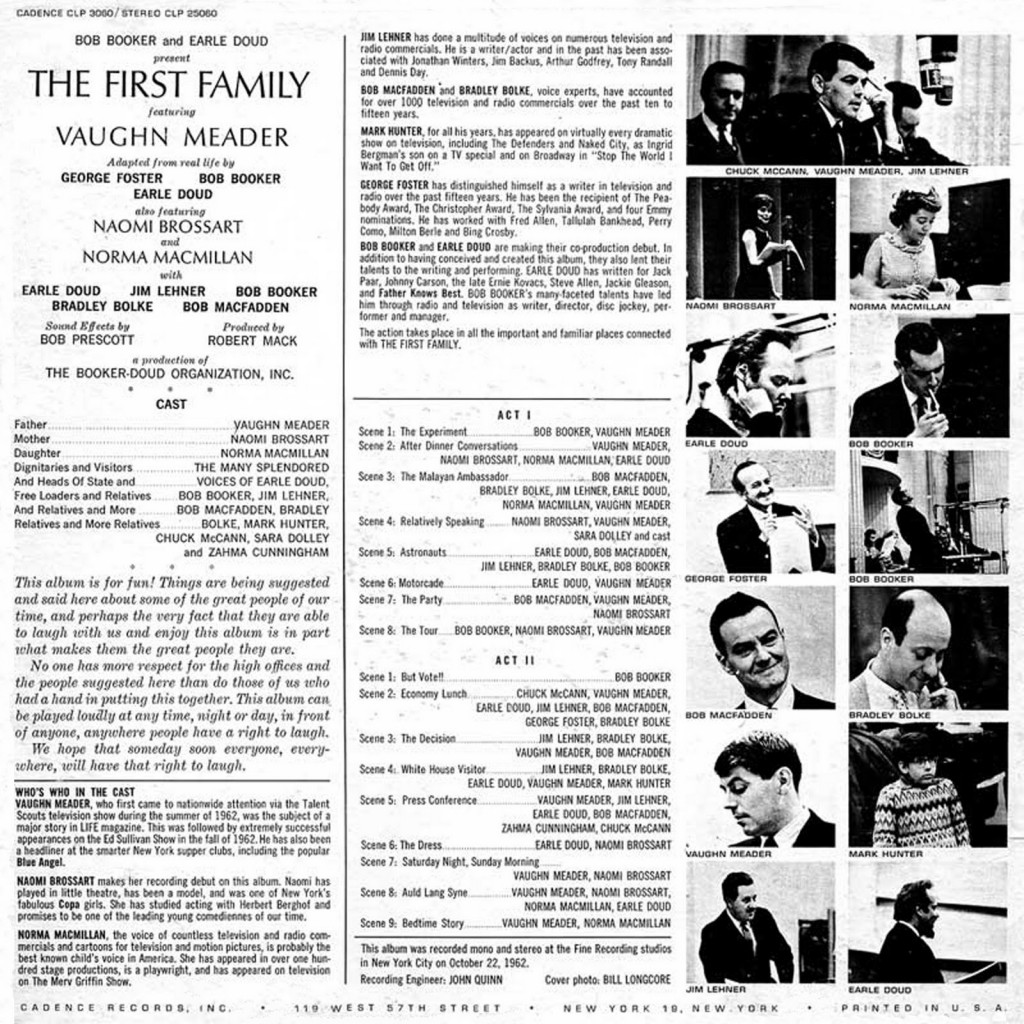

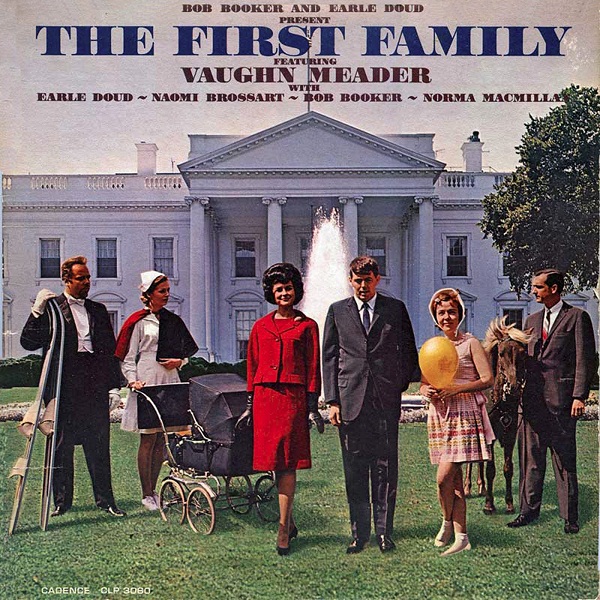

NEW YORK — In the history of the phonograph record business there has never been an album that has broken so many records, or set so many new ones as the Cadence LP of “The First Family,” with Vaughn Meader and friends. It has sold more than any other LP ever issued, more than 4,000,000 as of January 10., just about two months after it was first released (November, 1962).

It holds all-time records for the number of LP’s sold in a day, a week and a month, and it has set new marks at RCA Custom where 2 million were pressed (in three busy weeks), and at Columbia’s custom plants, where 1 million were made. Of the 4 million shipped, Cadence billed and shipped 3,600,000, the other 500,000-plus being shipped at no charge as part of the firm’s four for 25, or 16 per cent merchandise deal.

That Cadence was able to meet the instantaneous and furious demand for the album — which ran as high as 1 million a week — within days or even hours of the orders almost from the time the record started to jet off, is a tribute to the firm’s quickly devised and ingenious production schedule Cadence undertook marketing this particular LP.

This schedule was probably the most massive ever attempted in the record business. It is also a tribute to the printing firms, the album fabricators, the pressing plants and the trucking firms, who met the intricate, rush production schedules. When it is noted that Cadence, like many other independent record labels, has no pressing facilities of its own, and that the demand for “The First Family” came at the height of the Christmas buying season, the production job accomplished becomes even more extraordinary.

Something else that cannot be overlooked is the role played in “The First Family” story by Cadence distributors, who did a back-breaking job in getting the albums to dealers. The album set all-time marks with every distributor who handled it; Alpha Distributors in New York moved 300,000 “First Family” LP’s in 16 (around-the-clock) scheduled days.

In The Beginning

When Cadence shipped samples of its LP, “The First Family,” the week of November 5, Cadence President Archie Bleyer and sales promotion chief Bud Dollinger felt they had a pretty good album. They thought it would sell at least 100,000, and with luck double or triple that, which would be a substantial sale for a new and unknown comic named Vaughn Meader. Production manager Bob Mack had place a pressing order for about 15,000. Because Meader was due to be on the Ed Sullivan Show on Sunday, November 11 (1962), Cadence had shipped its new York distributor, Alpha, 100 copies to place in key store windows in Manhattan alone.

Monday, November 12, was a quiet day at Cadence, the firm’s last quiet day for about two months. Tuesday, November 13, Bob Booker, co-producer of the “First Family” set, brought the LP to his old friend, Stan Burns, WINS in New York. Burns listened to parts of it and then put in on the air immediately and kept playing tracks from the LP during his entire show.

The phone started ringing at Alpha Distributors from dealers wanting copies. Harry Apostelaris of Alpha Distributors called Cadence and ordered 400 sets. Pete Myers of WINS continued to play the album on the station that same day. A little later Bob and Ray on WHN played excerpts of the LP on their show. The phones kept jumping on Alpha. Apostelaris excitedly picked up the phone again and called Cadence. This time he placed an order for 20,000 copies for the LP.

Taking Off

Wednesday morning, November 14, Klavan and Finch started to expose tracks from the album over WNEW. By that afternoon almost every disk jockey in New York was “on” the LP. Alpha’s order that day totaled 20.000. He ordered another 25,000 copies from Cadence.

Thursday, November 15, the “First Family” was the talk of the town. Consumers were clamoring for copies. Alpha ordered another 25,000 for a whooping total of 70,500 in four days.

Cadence executives knew now they had a smash, though they still didn’t know how big a smash it really had become. They shipped 15,868 copies to Alpha. That order was quickly snapped up. And they stilled owed Alpha 55,000. They anticipated Alpha would order another 25,000 the next day, Alpha ordered another 50,000 instead!

Here Mack decided he couldn’t get enough pressing facilities on one coast to handle the album. He booked a flight to Los Angeles on Sunday, November 18 (the earliest reservation he could obtain), and assigned his assistant, Peter Hess, to fly to Indianapolis to set a pressing, printing and album facilities there. They were both met in the different airports by manufacturers and printers and album people. They both took with them from positives and progressive proofs of the album covers that they had ordered from their New York printers.

“I wasn’t worried about getting pressings in time,” Mack said, ” “or even the albums. It was the four-color covers that concerned me.”

Coast Opens Up

On Friday, November 17, Ralph Story on KNX in Los Angeles, started to lay the excerpts for the Meader disk. That same day a West Coast dealer called Dollinger and Bleyer in New York and demanded 200 records. When they told him they were clean, he screamed for copies without covers. They refused.

Said Dollinger: “If we did that we we would have made it possible for counterfeiters to sell “First Family” LP’s all over the U.S. without covers. We told him he would have his 200 copies Tuesday. He did.”

By Monday, November 19, “First Family” records were being pressed all over the country. RCA Victor was making the albums in Rockaway, New Jersey; Indianapolis and Los Angeles. Columbia Records were pressing in Los Angeles; Bridgeport, Connecticut and in Pittman, New Jersey. Capitol was pressing the LP at its Scranton, Pennsylvania plant; Monarch at its Los Angeles plant; Sonic at Hicksville, Long Island; and All Disks in Roseville, New Jersey.

Printing of the “First Family” album covers and liners was assigned and done by Lithograph Corporation of America in Bridgeport, Burford Printing in Indianapolis and Imperial in Hollywood.

Also, albums were being manufactured by Country Box, Modern Album Company and by Globe in New York; Modern Album in Terre Haute, Indiana and Hollywood, and Rek-O-Pak and Imperial in Hollywood.

The printers, jacket manufacturers and pressing plants came through “splendidly,” according to Mack.

“They gave us unstinting cooperation. Victor had to take its Elvis Presley record of “Girls, Girls, Girls” off their presses to make “First Family” LP’s and they couldn’t turn them over to Columbia or Capitol, for we had those plants locked up, too,” he said, “but they came through.”

Columbia, with its own Christmas stuff rolling, also made room for us at Bridgeport and Pittman. They were all wonderful.”

No Holidays

Dollinger, Mack and Hess set up an over-all production chart to check every printer, jacket manufacturer and pressing plant in New York, Los Angeles and Indianapolis, the three production areas. They were on the phone day and night for almost four weeks, including Thanksgiving Day, Saturdays and Sundays. They lined up trucks to take the finished covers and liners to the jacket manufacturers and the jackets to the pressing plants. They then allocated the completed albums to their 32 distributors.

“You should see our phone bills,” said Mack.

“Our distributors were incredible,” said Dollinger. “They would send their own trucks to the plants to pick up the finished merchandise. Our Baltimore distributor used to have a truck waiting at the Victor Rockaway plant every day, and so did our Boston distributor.”

In New York demand for albums were so great that dealers would come over in their own cars or in taxicabs and help unload the trucks arriving with “First Family” albums at the Alpha warehouse on 10th Avenue. They were billed as they shoved the albums into their cars or taxicabs before speeding away. The same scene was being enacted in Los Angeles.

By November 23, about ten days after the record had broken in New York, Cadence had billed and shipped more than 900,000 LP’s, excluding the complimentary copies. The firm had shipped more than 135,000 to Alpha in New York, and it still owed 150,000 on back-order.

All The Way

As of November 30 the firm has billed and shipped 2,100,000 records, again excluding the complimentary albums which add up to about 16 per cent over the top. As of December 7, total billed and shipped was 2,800,000; December 14, 32,000,000; December 21, 3,400,000; December 28, 3,500,000; January 5, 3,585,000; January 10, 3,600,000.

The album is still selling at a rate of about 10,000 a week. Still, shipments have been carefully watched to the extent that right now, according to Dollinger and Mack, they do not believe there are more than 10,000 albums in the field that might be returned. “Our distributors are clean,” says Dollinger, “and we think dealers are stock clean insofar this LP as well.”

Just after the album really took off, and Cadence had shipped its first million LP’s, a remarkable thing happened with the firm’s distributors. It started when the firm’s Hartford distributor, Eastern, called to place a large order. “I’m sending Archie a check for $50,000,” said Eastern chief Dick Godlewski. “If I don’t pay it now I’ll never catch up, and I know Archie needs it.” Several other distributors, almost simultaneously, did the same.

Distributors Came Through

Although Cadence is a strong, independent label, with a solid credit rating and cash in the bank, the help from distributors were welcomed because of the astronomical sums being laid out by the firm.

From then on the firm called on its distributors to send something with its orders. Distributors all came through with cash, many of them going out and getting loans on their accounts receivable.

At the height of the frantic demand, Dollinger was receiving impassioned calls from stores, racks and chains. He had one order for a direct sale of 100,000 LP’s at $2.10 each and turned it down. He told the store to see the local Cadence distributor.

“We turned down all direct sales,” said Dollinger, “since we believe in letting our distributors handle all accounts.”

Dollinger added that the “First Family” album has created an interesting development as far as dealers and distributors are concerned.

“In talking to our distributors, we have found that a number of them have got back some accounts that were being serviced by rack jobbers. It seemed that when they wanted the “First Family” they found they could get it more quickly from distributors than from the rackers. Distributors say that a number of chains have returned to them and intend to stay with them because of better service.”

Could another album ever rise to repeat the fantastic “First Family” story? Dollinger: “I don’t know whether there will ever be another that sell so many copies in such a short period of time. But we now know not only that an album can sell 4 million in a few months, but that it is also possible to produce 4 million and get them to the stores while they’re hot.” END.

— BOB ROLONTZ

(Photo: LIFE Magazine; February 8, 1963)

(Information and news source, Billboard; January 26, 1963).

![]()